Looking Good Tips About How Does A Torque Meter Work

What Is Torque Meter At Michael Madden Blog

Understanding Torque Meters

1. What Exactly Is a Torque Meter?

Ever wondered how mechanics tighten bolts with such precision? Or how engineers ensure a machine's components aren't stressed beyond their limits? The answer, quite often, lies in a clever little device called a torque meter. You might think of it as a highly specialized wrench, but it's so much more than that. A torque meter, at its heart, is a tool for measuring the rotational force, or torque, applied to an object. "Torque meter" is a noun, by the way, the star of our show! It lets us quantify that twisting effort, ensuring we're not overtightening (and potentially snapping) something delicate, or undertightening and risking it coming loose later.

Think of tightening the lug nuts on your car's wheels. Too tight, and you risk stripping the threads or warping the rotor. Too loose, and your wheel might just decide to part ways with the car while you're cruising down the highway — definitely a less-than-ideal scenario! A torque meter allows you to tighten those nuts to the manufacturer's exact specification, ensuring safety and longevity.

But it's not just for cars. Torque meters are used in a dizzying array of industries, from aerospace (ensuring aircraft components are properly secured) to manufacturing (controlling the tightness of screws in electronic devices). Anywhere precise rotational force is critical, you'll find a torque meter hard at work.

So, the next time you see someone using one, remember it's not just about tightening something; it's about applying controlled, measured force to ensure things are just right. It's the Goldilocks of the wrench world!

2. Different Types of Torque Meters

Now, not all torque meters are created equal. Just like there are different types of screwdrivers for different screws, there are different types of torque meters for different applications. The most common type you might encounter is the mechanical torque wrench. This type typically uses a spring-loaded mechanism and a scale to indicate the amount of torque being applied. They are relatively simple to use and generally more affordable.

Then there are electronic torque meters. These are the more high-tech cousins of the mechanical variety. They use strain gauges and electronic circuitry to measure torque with incredible accuracy. The readings are displayed digitally, making them easy to read and record. Electronic torque meters are often used in applications where extreme precision is paramount, such as in research and development or quality control.

Another category is hydraulic torque wrenches. These powerhouses are used for extremely high torque applications, like tightening bolts on pipelines or heavy machinery. They use hydraulic pressure to generate immense force, making them indispensable in industries like oil and gas, and construction.

Choosing the right type of torque meter depends entirely on the specific task at hand. Consider the required accuracy, the torque range needed, and the environment in which it will be used. It's all about matching the right tool to the job!

How Does a Torque Meter Work (The "Keyword" in Action!)

3. The Inner Workings

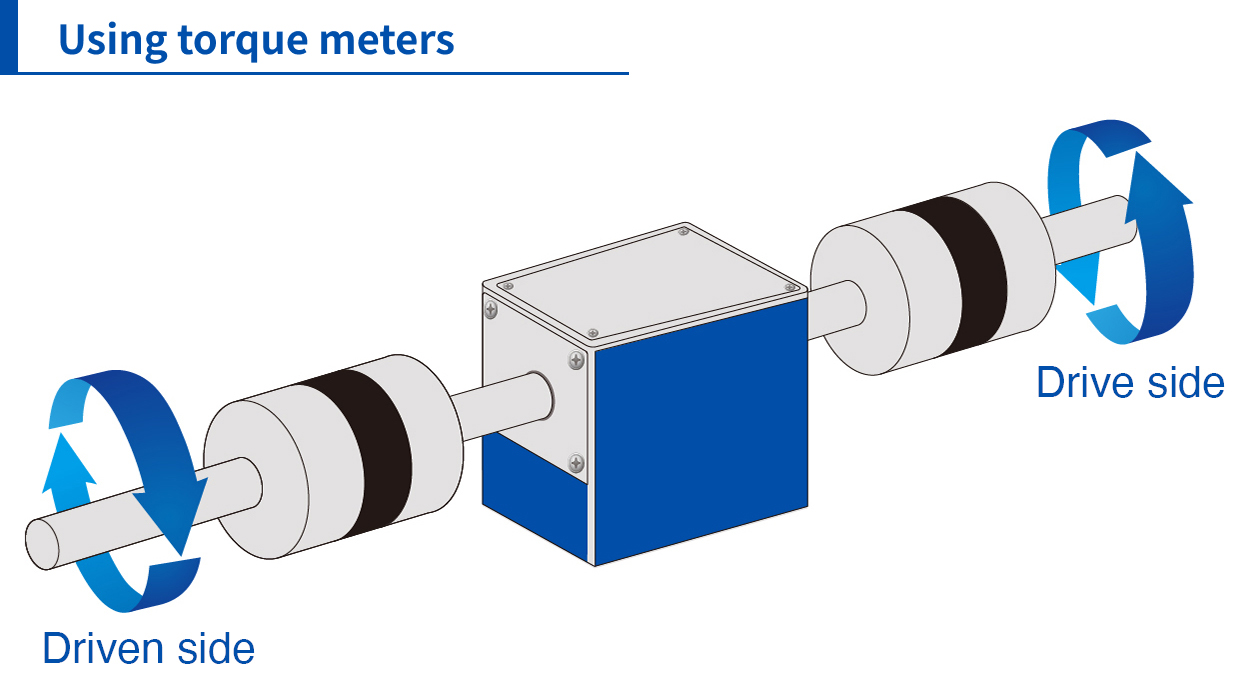

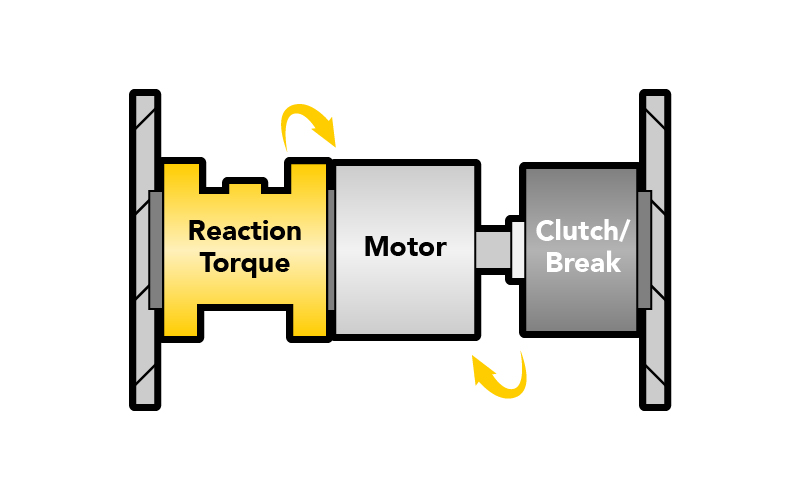

Okay, let's dive into the core of the matter: how does a torque meter work? Whether it's a simple mechanical wrench or a sophisticated electronic device, the fundamental principle remains the same. The torque meter measures the twisting force applied to a fastener or component.

In a mechanical torque wrench, as you apply force to the handle, it deflects a spring. The amount of deflection is directly proportional to the torque being applied. This deflection is then translated to a scale, allowing you to read the applied torque value. It's a beautifully simple, yet effective, system.

Electronic torque meters take a different approach. They utilize strain gauges, which are small electrical resistors that change their resistance when subjected to strain or deformation. When torque is applied, the strain gauges mounted on the torque meter's body experience strain, causing a change in their resistance. This change is then measured by electronic circuitry and converted into a digital display of the torque value.

Hydraulic torque wrenches use a completely different method. They employ hydraulic pressure to drive a ratcheting mechanism. As hydraulic pressure is applied, it moves a piston, which in turn rotates the wrench. The amount of torque applied is directly related to the hydraulic pressure, which can be precisely controlled and monitored.

4. From Twisting to Numbers

The process of using a torque meter is generally straightforward, but precision is key. First, you need to select the correct socket or attachment for the fastener you're working with. Then, set the desired torque value on the torque meter, if applicable. For mechanical torque wrenches, this usually involves adjusting a handle or dial until it aligns with the desired torque marking. For electronic torque meters, you'll typically enter the desired value on the digital display.

Next, carefully position the torque meter on the fastener and begin applying force. As you apply force, watch the indicator on the torque meter. For mechanical torque wrenches, you'll see the scale moving. For electronic torque meters, the digital display will show the real-time torque value.

Continue applying force until you reach the desired torque value. Most torque meters will provide some kind of indication when the target torque is reached, such as a click (in the case of mechanical wrenches) or an audible beep (in the case of electronic meters). Once you hear or see the indication, stop applying force. You've successfully torqued the fastener to the specified value!

Remember to always use a smooth, steady motion when applying torque. Jerky or uneven movements can lead to inaccurate readings. And, perhaps most importantly, always double-check the manufacturer's specifications for the correct torque value for the fastener you're working with.

Mechanical

Why Accuracy Matters

5. The Ripple Effect of Precision

You might be thinking, "Okay, so it measures twisting force. Big deal!" But the accuracy of a torque meter has far-reaching consequences, especially in critical applications. Imagine a scenario where you're assembling a jet engine. Each bolt and fastener must be tightened to a precise torque specification to ensure the engine's structural integrity and performance. An improperly torqued bolt could lead to catastrophic failure during flight, with potentially disastrous results.

In the automotive industry, accurate torque measurement is crucial for ensuring the safety and reliability of vehicles. Under-torqued bolts could cause components to loosen or separate, leading to accidents. Over-torqued bolts, on the other hand, could damage threads or weaken materials, also increasing the risk of failure.

Even in less critical applications, accuracy still matters. Consider assembling furniture. If you overtighten the screws, you could strip the threads in the wood, resulting in a wobbly and unstable piece of furniture. Conversely, if you undertighten the screws, the furniture might not be sturdy enough to withstand everyday use.

The bottom line is that accuracy is paramount when it comes to torque measurement. It ensures the safety, reliability, and performance of everything from aircraft engines to everyday household items. Investing in a quality torque meter and using it properly is a worthwhile investment, no matter the application.

Tips for Using a Torque Meter Like a Pro

6. Level Up Your Torque Game

Using a torque meter isn't rocket science, but there are a few tricks to mastering it. First, always calibrate your torque meter regularly. Over time, the internal components of the meter can drift, leading to inaccurate readings. Regular calibration ensures that your torque meter is providing accurate measurements. Many calibration services are available that can perform this task for you.

Second, apply force smoothly and steadily. Avoid jerky or uneven movements, as these can introduce errors into the measurement. A slow, consistent application of force will yield the most accurate results.

Third, be mindful of the angle of application. Torque meters are designed to be used perpendicular to the fastener. Applying force at an angle can throw off the reading and result in an inaccurate torque value.

Finally, store your torque meter properly. Keep it in a clean, dry place, away from extreme temperatures and humidity. This will help prolong its life and maintain its accuracy.

Frequently Asked Questions (Because You Probably Have Some!)

7. Your Torque Meter Questions Answered

Q: How often should I calibrate my torque meter?

A: It depends on how frequently you use it, but a good rule of thumb is to calibrate it at least once a year, or more often if you use it heavily or in critical applications.

Q: Can I use a torque meter to loosen bolts?

A: While some torque meters can be used to measure torque in both directions, it's generally not recommended to use them for loosening bolts. The sudden force required to break a bolt loose can damage the torque meter's internal components.

Q: What's the difference between foot-pounds and Newton-meters?

A: These are simply different units of measurement for torque. Foot-pounds (ft-lb) is commonly used in the United States, while Newton-meters (Nm) is the standard metric unit. You can easily convert between the two using online converters or calculators.

Q: Are digital torque meters more accurate than mechanical ones?

A: Generally, yes. Digital torque meters often offer higher accuracy due to their use of strain gauges and electronic circuitry, which provide more precise measurements compared to the spring-loaded mechanisms in mechanical torque wrenches. However, a well-maintained and calibrated mechanical torque wrench can still provide accurate results for many applications.