Outrageous Tips About Why Do We Measure Torque

Why All the Fuss About Torque? Understanding Its Importance

1. The Torque Tale Begins

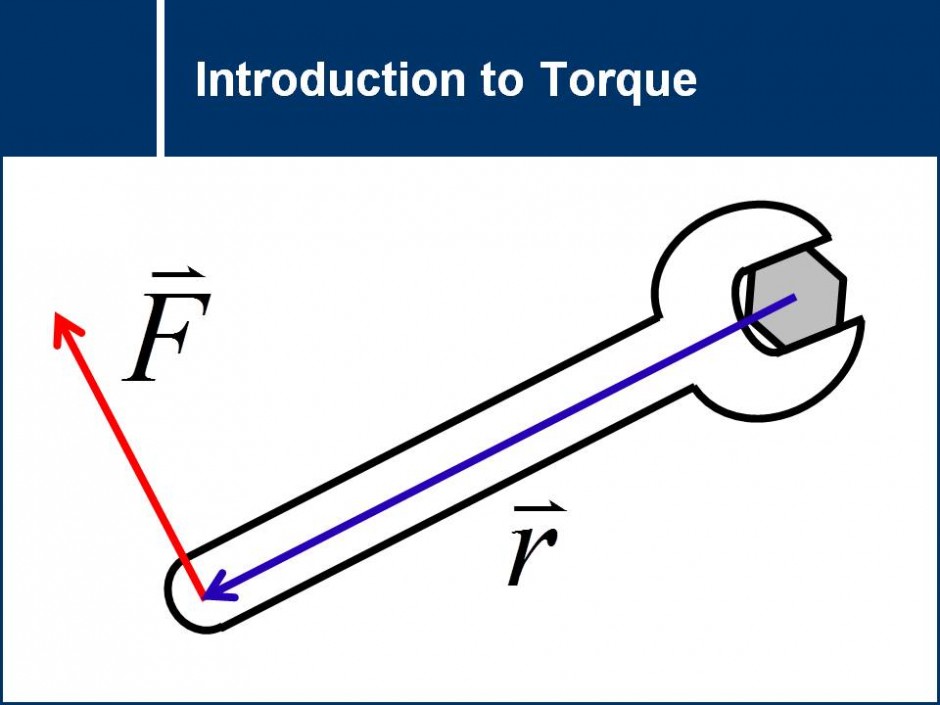

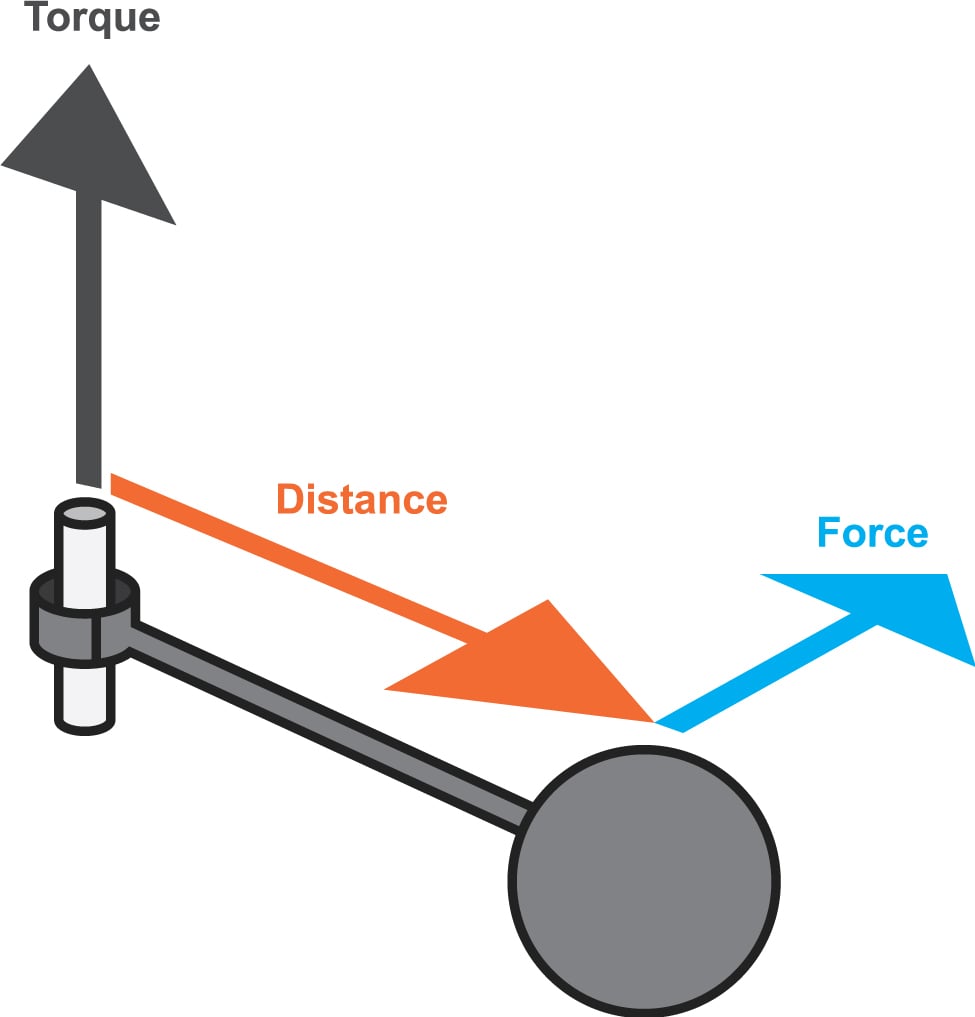

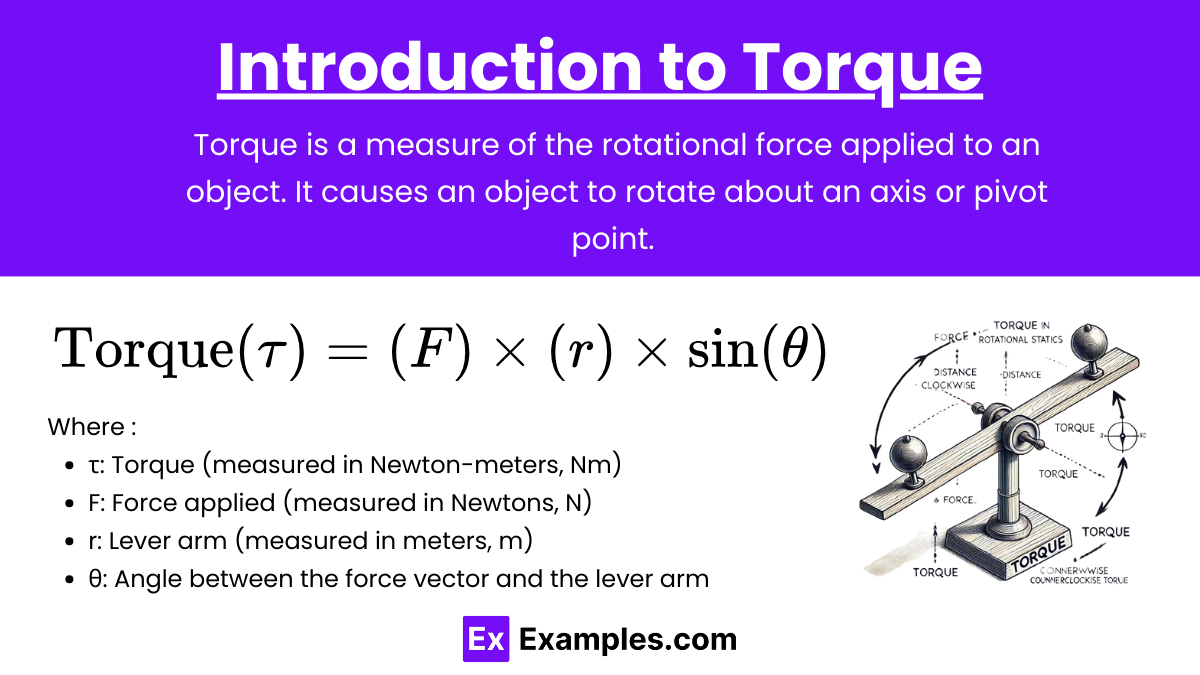

Ever wondered why mechanics and engineers seem so obsessed with torque? Its not just a fancy word they throw around to sound smart. Torque, at its heart, is a twisting force that causes rotation. Think of it as the oomph behind turning a wrench, opening a stubborn jar, or even the power that gets your car moving. Without torque, things just wouldn't... well, turn.

So, why do we measure torque? The simple answer is: because it's crucial for understanding and controlling rotational motion. But let's dig a little deeper than that, shall we? Measuring torque allows us to ensure things don't break, perform as expected, and, crucially, stay safe. Imagine building a bridge without knowing the twisting forces it would endure. Yikes!

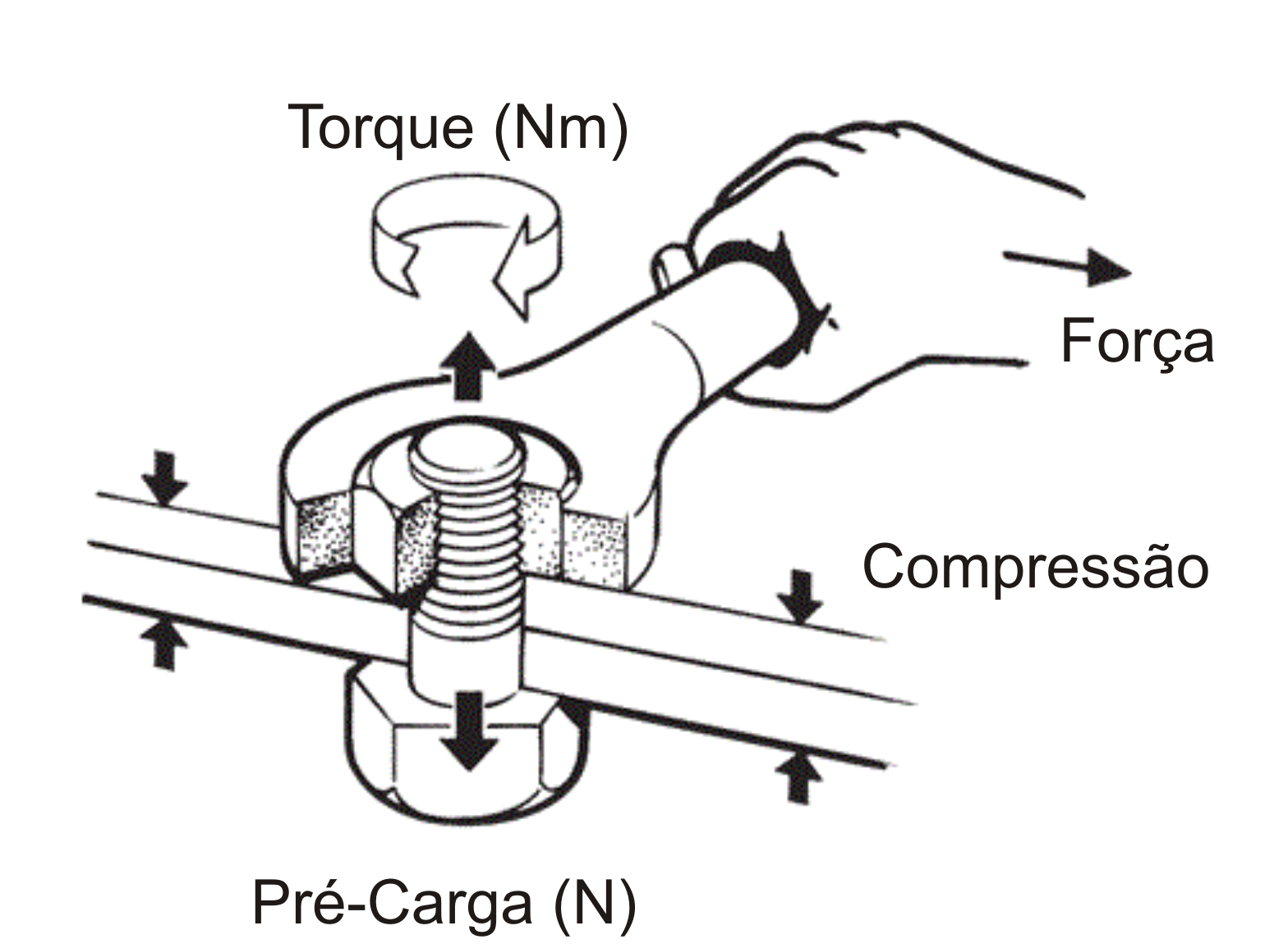

Think about tightening bolts on a car engine. Too little torque, and the parts might come loose, leading to a catastrophic failure. Too much, and you risk stripping the threads, weakening the connection. Goldilocks would be proud — you need it just right! Measuring torque gives us that "just right" feeling, or rather, that "just right" value.

From tiny electronic components to massive industrial machinery, torque plays a vital role. And understanding how much torque is being applied, and ensuring it's within acceptable limits, is paramount for reliability and performance. It's the unsung hero of rotational motion, quietly working behind the scenes to keep the world turning (literally!).

Cinemática E Dinâmica De Rotações Leis Conservação

Unveiling the Reasons

2. Accuracy is the Name of the Game

Imagine baking a cake without measuring the ingredients. It might taste okay, but chances are it won't be the masterpiece you envisioned. The same principle applies to torque. Guessing or eyeballing it just won't cut it in situations where precision matters, and frankly, that's most situations involving rotational forces.

Accurate torque measurement is essential for several key reasons. Firstly, it ensures the integrity and reliability of mechanical systems. From the assembly line where cars are put together, to the operating room where medical devices are used, precise torque application can prevent failures and extend the lifespan of equipment. That saves money and, more importantly, prevents accidents.

Consider the aerospace industry. The components used in aircraft are subjected to extreme stress and vibrations. If the torque on the fasteners is not within specifications, it could lead to catastrophic failures mid-flight. Therefore, accurate torque measurement is not just a recommendation; it's a matter of life and death.

Furthermore, accurate torque measurement is vital for quality control and standardization. It helps manufacturers ensure that their products meet specific performance requirements and comply with industry standards. This not only enhances the reputation of the company but also provides consumers with confidence in the safety and reliability of the products they purchase.

Tools of the Trade

3. From Wrenches to Wonders

So, how do we actually measure torque? Thankfully, we're not left to rely on sheer guesswork. A range of specialized tools and techniques exist to accurately determine the amount of twisting force being applied. These tools vary in complexity and application, catering to different needs and industries.

The simplest and most common tool is the torque wrench. This handy device allows users to apply a specific amount of torque to a fastener, such as a bolt or nut. Torque wrenches come in various types, including click-type, beam-type, and electronic. The click-type wrench is particularly popular, as it provides an audible click when the desired torque is reached, preventing over-tightening.

For more sophisticated applications, torque sensors and transducers are used. These devices convert the applied torque into an electrical signal, which can then be measured and displayed on a digital display. Torque sensors are often integrated into automated assembly lines and testing equipment, providing real-time feedback and control.

In addition to these common tools, there are also specialized devices for measuring torque in specific applications. For example, dynamometers are used to measure the torque and power output of engines and motors. These devices provide valuable data for performance analysis and optimization.

O Que é A Medida Nm De Torque?

Beyond Nuts and Bolts

4. Torque's Triumphant Tour Across Industries

You might think measuring torque is only important for mechanics and engineers working on cars or machines. But the reality is that torque measurement plays a critical role in a surprisingly wide range of industries and applications. It's not just about tightening nuts and bolts; it's about ensuring things work correctly, safely, and efficiently across various fields.

In the medical field, for example, torque measurement is used to ensure the proper functioning of surgical instruments and implants. Precise torque control is essential when inserting screws into bones during orthopedic surgery, preventing damage to the surrounding tissue. Similarly, torque measurement is crucial in the manufacturing of medical devices, ensuring that they meet stringent performance standards.

The food and beverage industry also relies on torque measurement. From tightening bottle caps to controlling the mixing of ingredients, torque plays a vital role in ensuring product quality and consistency. Proper torque application prevents leaks and contamination, ensuring that food and beverages are safe for consumption.

Even in the realm of sports and recreation, torque measurement is important. Think about the tension on the strings of a tennis racket or the torque applied to the pedals of a bicycle. These factors can significantly impact performance and comfort. Manufacturers use torque measurement to optimize the design and performance of sporting equipment.

Torque

5. Ensuring Safety and Performance through Precise Torque

At the end of the day, the reason we measure torque boils down to one crucial point: it ensures safety and optimizes performance. It's not just about getting the job done; it's about getting it done right, every single time. Whether it's building a bridge, assembling a car, or performing surgery, accurate torque measurement is essential for preventing failures, extending the lifespan of equipment, and protecting lives.

Imagine the consequences of neglecting torque measurement in critical applications. Bridges could collapse, airplanes could crash, and medical devices could malfunction. The potential for disaster is simply too great to ignore. By embracing the principles of precise torque measurement, we can build a safer and more reliable world.

But it's not just about avoiding disasters. Accurate torque measurement also leads to improved performance and efficiency. When components are properly tightened, they are less likely to loosen or fail under stress. This translates into reduced downtime, lower maintenance costs, and increased productivity. It's a win-win situation for everyone involved.

So, the next time you hear someone talking about torque, remember that it's more than just a number. It's a critical factor that influences the safety, reliability, and performance of countless products and systems. It's a testament to the power of precision and the importance of getting the details right. And hopefully, you now have a better understanding of why we obsess over it so much!

Frequently Asked Questions (FAQs)

6. Your Torque-Related Questions, Answered!

Q: What happens if I don't tighten a bolt to the correct torque?A: If you under-tighten a bolt, it might come loose over time, leading to instability or even failure of the assembly. Over-tightening, on the other hand, can strip the threads or damage the bolt itself, weakening the connection.

Q: Can I use any wrench as a torque wrench?A: No! A regular wrench won't give you an accurate reading of the torque being applied. Torque wrenches are specifically designed to measure and control the amount of twisting force.

Q: Are there different units for measuring torque?A: Yes, the most common units are Newton-meters (Nm) in the metric system and foot-pounds (ft-lbs) in the imperial system. Make sure you're using the correct units for your application!

Q: Where can I learn more about proper torque procedures?A: Many manufacturers provide torque specifications in their product manuals. You can also find resources online, such as engineering websites and forums, or consult with a qualified mechanic or engineer. Getting proper training is always a good idea for critical applications.